MS Dual Plate Check Valve: Reasons Why This Innovative Solution is Essential for Your Industrial Needs

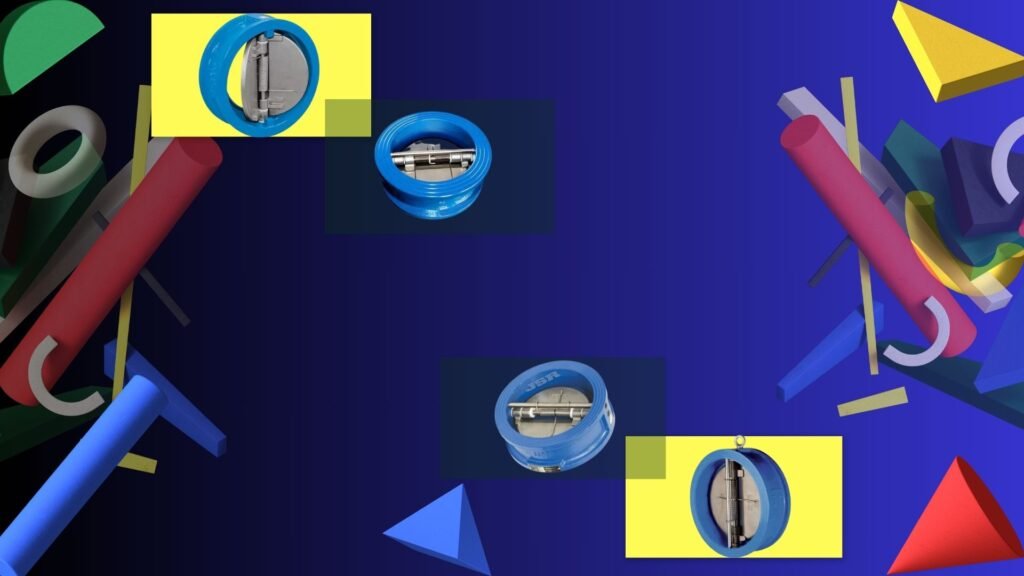

The MS Dual Plate Check Valve is a crucial part of fluid control systems that guarantee dependable and effective operation. Often called a butterfly check valve, folding disc check valve, or double-disc check valve, this innovative valve is made to work very well in a variety of industrial settings, especially those involving water and oil systems. We go over the main attributes and advantages of the MS Dual Plate Check Valve below, emphasizing why your next project should prioritize it.

1. Advanced Design for Enhanced Efficiency

The MS Dual Plate Check Valve has a special design in which the disc’s two halves flow forward toward the center line. By enabling a fluid and effective liquid flow, this device considerably lowers turbulence and guarantees peak performance. The dual plate design simplifies fluid dynamics, which makes it a perfect option for contemporary industrial applications in contrast to classic swing check valves, which can be unwieldy and ineffective.

2. Compact and Lightweight Construction

The MS Dual Plate Check Valve’s lightweight design and small size are two of its best qualities. This creative solution is easier to install and maintain, lowering labor costs and installation time, and it weighs significantly less than traditional check valves. Additionally, the lower footprint for more adaptable piping configurations, making it a perfect fit for facilities where space is at a premium.

3. Dependability in Durability

The MS Dual Plate Check Valve is made of premium materials and is designed to last a long time. Its sturdy design ensures dependable performance in challenging situations by withstanding high pressures and adverse conditions. Because they are investing in a product that offers both strength and resilience, users can rest easy.

4. Non-Return Functionality

The MS Dual Plate Check Valve is a non-return valve that keeps fluid systems from backflowing, preventing damage to pumps and other equipment. The efficiency and integrity of the system depend on this feature. Operators can improve the dependability of their fluid control systems by removing the possibility of reverse flow.

5. Versatile Applications

Numerous industrial applications, such as water supply systems, oil transportation, and other process industries, can benefit from the MS Dual Plate Check Valve. It is a useful addition to any fluid management system because of its adaptability. This valve is capable of handling both industrial oils and potable water with ease.

6. Cost-Effective Solution

Although high-quality valves may seem more expensive initially, the MS Dual Plate Check Valve’s longevity and effectiveness result in long-term savings. Over time, this valve pays for itself due to lower maintenance expenses, fewer replacements, and enhanced system performance. Any organization would be wise to invest in this cutting-edge solution.

7. Sustainability Benefits

The MS Dual Plate Check Valve promotes environmentally friendly operations in a time when sustainability is crucial. Its effective design reduces waste and energy use, which is in line with contemporary environmental objectives. Businesses may save money and help create a more environmentally friendly future by lessening the environmental impact of fluid systems.

Conclusion

More than just a part, the MS Dual Plate Check Valve is a potent remedy that improves fluid control systems’ dependability, durability, and efficiency. It meets the vital requirements of water and oil-related industries with its sophisticated design, lightweight construction, and adaptability. Purchasing this cutting-edge valve promotes economical operations and environmental practices in addition to ensuring peak performance.

For more information visit our website – https://expansiontankmanufacturer.com/

https://expansiontankmanufacturer.com/blog/?swcfpc=1

FAQ for MS Dual Plate Check Valve

1. What is an MS Dual Plate Check Valve?

The MS Dual Plate Check Valve is a type of non-return valve that features two disc halves that open and close with fluid flow. It is designed to prevent backflow in industrial fluid systems, making it ideal for applications involving water and oil.

2. What are the key features of the MS Dual Plate Check Valve?

Compact Design: Lightweight and smaller compared to traditional swing check valves.

Durable Construction: Made from high-quality materials for longevity and reliability.

Non-Return Functionality: Prevents backflow to protect pumps and equipment.

Versatile Applications: Suitable for various industrial applications, including water and oil systems.

3. What are the benefits of using the MS Dual Plate Check Valve?

Enhanced Efficiency: Streamlined fluid dynamics reduce turbulence.

Cost-Effective: Lower maintenance costs and longer service life lead to savings.

Sustainability: Supports eco-friendly operations by minimizing energy consumption.

4. In what applications can the MS Dual Plate Check Valve be used?

This valve is suitable for a wide range of applications, including:

Water supply systems

Oil transportation

Process industries

HVAC systems

Any industrial settings where fluid control is essential

5. How does the MS Dual Plate Check Valve compare to traditional check valves?

The MS Dual Plate Check Valve is generally stronger, lighter, and more efficient than conventional swing or lift check valves. Its design allows for better flow characteristics and requires less maintenance over time.